THE PROBLEM

Dredge Robotics was approached by a global mining company with a requirement to remove accumulated organic sediment from a lined tank with a thin and fragile liner. The tank had accumulated a blanket of sediment that was impacting the operation of the asset and required immediate rectification to avoid downstream impacts. The Client had explored other options to execute this work scope however none were deemed appropriate for the requirements of the project based on risk profile or cost.

THE CHALLENGE

The project was highly time sensitive and the asset was unable to be taken offline without significant cost implications. The liner integrity was critical and it was deemed that the consequence of liner damage would be very substantial.

OUR SOLUTION

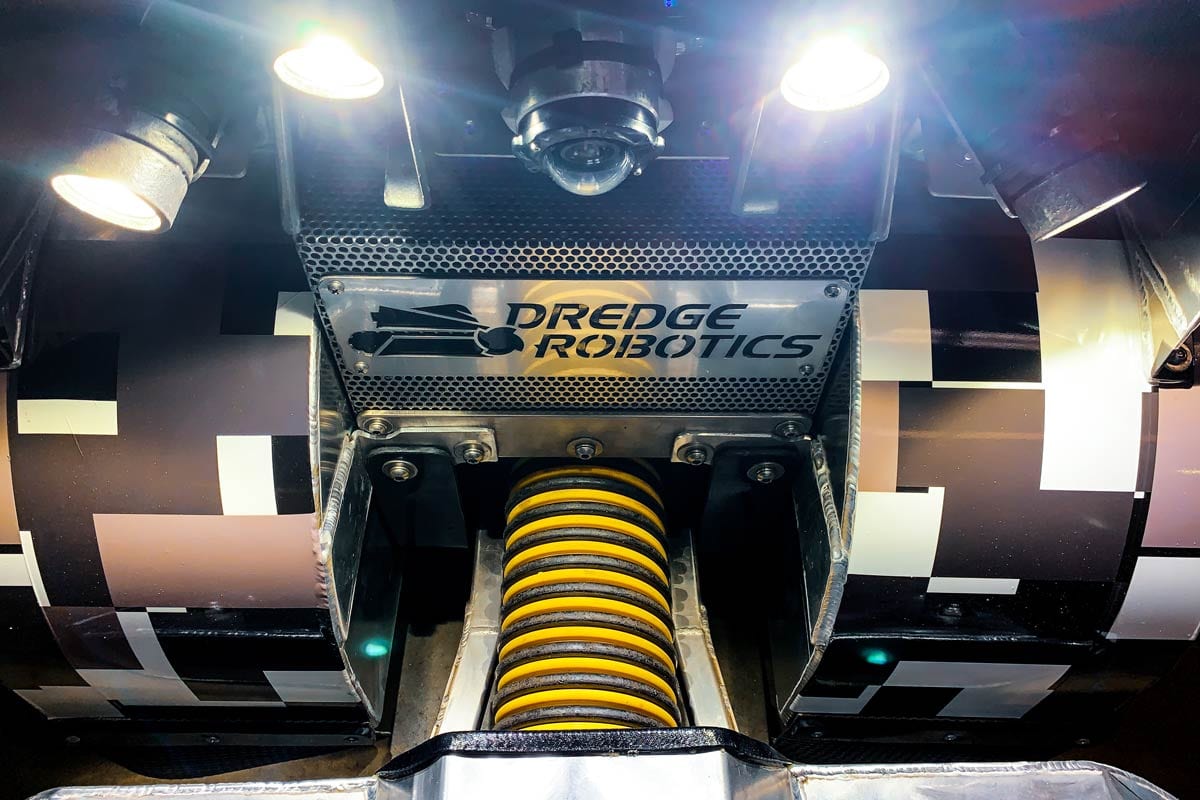

After working through a risk assessment process with the Client, Dredge Robotics were able to deploy one of our proprietary liner-safe dredging robots to this site inside a short time frame to meet the Project requirements. The tank had to be dredged in a slow and methodical fashion to maintain required water levels and minimise turbidity during the operation.

No human entry to the asset was required and the project was completed without incident, both on time and on budget. This project was so successful that this has now become the standard maintenance protocol to clean tanks of this type for this site, and the scope has since been successfully completed twice since the initial clean. Dredge Robotics continue to work very closely with this Client to engineer new solutions to challenging problems such as this one.